Heating film is a type of electric resistance heating, providing relatively low temperatures (compared to conventional heating systems) over large areas. Carbon film heating can be used to replace conventional heating systems as a primary heat source, or to supplement and enhance the comfort of existing systems. But where did heating film come from?

The orogin of carbon heating film – Ondol

Ondol, also called gudeul (Korean 구들) in traditional Korean architecture, is a floor heating system used for over 7,000 years in Korea, according to archaeological findings. It uses direct heat transfer from the “stove” through a flue to the bottom of a thick masonry floor. Many modern Korean homes use a radiant floor heating system called ondol, which refers to this traditional heating system. In fact, Koreans refer to any heating system in the home as ondol.

Early ondol started as gudeul, providing heating for the house and cooking space. When a fire was lit in the oven to cook rice for dinner, the flame extended horizontally because the entrance to the flue was next to the oven. This arrangement was necessary because it did not allow the smoke to spread upwards, which would cause the flame to burn too quickly and go out early. As the flame passed through the entrance to the flue, it was carried along with the smoke through a network of passages. Entire rooms were built on top of the flue to create rooms with underfloor heating. With traditional ondol heating, the floor closer to the furnace was usually warm enough and the hottest spots were reserved for the elderly and rare guests.

Technicky vychází moderní ondol ze stejného konceptu jako podlahové sálavé vytápění, které vynalezl americký architekt Frank Lloyd Wright. Ten se zajímal o asijskou architekturu a na tento nápad přišel při návštěvě domu japonského šlechtice, kde navštívil čajovnu, která se pocitově lišila od zbytku domu a Wrighta naprosto ohromila. Jako vytápěcí systém byl v místnosti použit právě korejský ondol. Stejnou myšlenku pak převzal a vytvořil topný systém vhodný pro americké domy. Wright vynalezl moderní sálavé podlahové vytápění, které využívá horkou vodu protékající potrubím namísto horkého vzduchu skrze kouřovody. Ve druhé polovině 20. století společnost začala mnohem více řešit životní prostředi a nad tradičním způsobem vytápění se začaly stahovat mračna. Vznikla zde tedy potřeba vytápět korejské domy jiným zdrojem tepla, než je spalování dřeva a briket. Samotná topná fólie je variantou moderního ondolu, která ale nepotřebuje teplou vodu ani potrubí, protože je plně elektrická. Tento typ vytápění se používá hlavně v asijských zemích, zejména v Koreji odkud se jeho popluarita rozšiřuje do celého světa.

Technically, the modern ondol is based on the same concept as underfloor radiant heating, which was invented by the American architect Frank Lloyd Wright. He was interested in Asian architecture and came up with the idea when he visited the home of a Japanese nobleman, where he visited the tea room, which felt different from the rest of the house, and Wright was completely impressed. The heating system in the room was a Korean ondol. He then took the same idea and created a heating system suitable for American homes. Wright invented modern radiant floor heating, which uses hot water flowing through pipes instead of hot air through flues. In the second half of the 20th century, society became much more environmentally conscious and the clouds began to lift over traditional heating methods. Thus, there was a need to heat Korean homes with a heat source other than burning wood and briquettes. The heating film itself is a variant of the modern ondol, but it does not need hot water or pipes because it is fully electric. This type of heating is mainly used in Asian countries, especially in Korea from where its popularity is spreading worldwide.

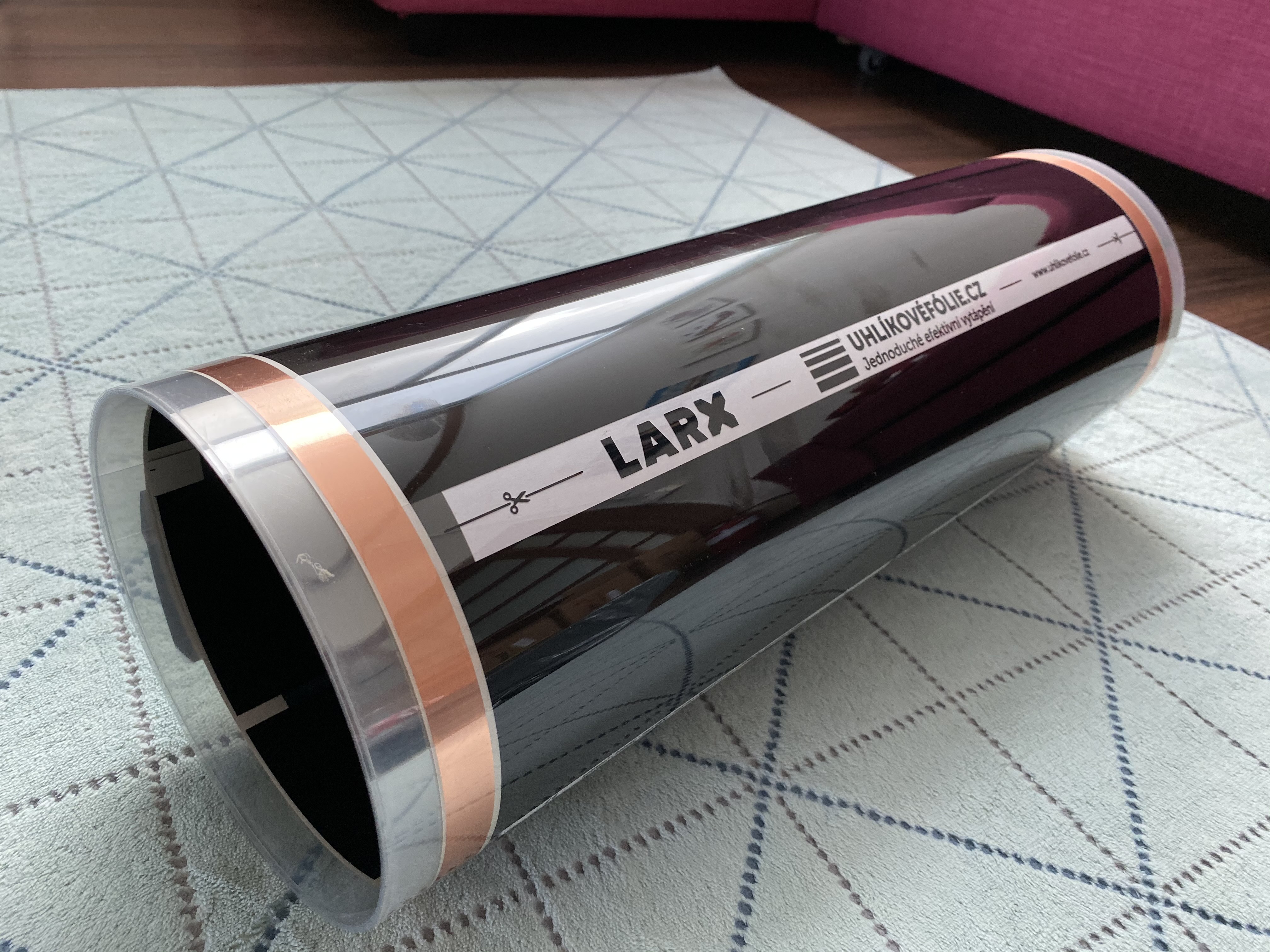

The vast majority of carbon foils are currently manufactured in South Korea, which is why we went there a few years ago. South Korea is not only one of the most technologically advanced countries in the world, it also has much higher labour productivity than most of Europe. We visited dozens of underfloor heating and carbon film manufacturing plants (Russia, the USA and the north of Asia largely source this technology). We tried out different manufacturers and their products. Together with (in our opinion) the most innovative South Korean manufacturer, we developed LARX durable carbon film, directly tuned for the European market and the requirements of the local market. Its construction, durability and stability make it suitable for single family homes and large development projects.

Carbon heating film production

The thickness of the electric heating film is up to 1 mm, so they are very thin and negligible in the overall height of the floor composition. Production starts with a very thin layer of plastic film, which is produced by synthesizing polyethylene (PE) and polyethylene terephthalate (PET). The carrier part of the heating film is made up of two built-up strips of this plastic film, between which a resistive heating element is applied, which is made up of carbon paste. This paste is produced by pressing fine carbon dust, which is used, for example, as a dye in printer ink. The process of applying the carbon paste to the web is also similar to printing. The power output of the heating film is influenced by the concentration of carbon in the paste. There are copper strips on the longitudinal edges of the heating film that connect the individual strips of carbon paste. Power cables are attached to these strips by means of crimp connectors. The ends of the film and all joints must always be carefully insulated.

Are you interested in our implementation of the LARX CARBON-FILM.COM heating system? Do not hesitate and send us your project via the contact form and we will price the heating system for you without obligation.

Česky

Česky