Carbon heating films are a simple, efficient and maintenance-free heating method. The installation of the heating film itself is very easy and can be carried out by yourself if the installation instructions are followed. There are several options where to install the heating film in the floor construction – under the screed (concrete, anhydrite) or directly under the prefabricated floorboards.

Electric underfloor heating using heating film offers many advantages. Among the greatest are low acquisition and operating costs, maintenance-free operation and whole-surface operation. Thanks to its thickness, the LARX CARBON-FILM.COM heating system is suitable for all types of buildings and renovations. Heating films are a low-temperature type of heating. This means that they do not cause dust swirling or air drying, so they are an ideal type of underfloor heating for allergy sufferers, asthmatics and other people with respiratory problems.

Carbon film is a heat source that converts electrical energy into heat with an efficiency of 99% (100 W of electrical energy produces 99 W of heat) locally, the conversion of electrical energy into heat takes place directly at the point of need (the heated room). Carbon film can act as a main or supplementary heat source, ideally in conjunction with photovoltaic panels and home batteries.

Heating film installation options

The LARX CARBON-FILM.COM heating system has a number of indisputable advantages. Maintenance-free and low-cost operation, low space requirements in the floor, precise regulation and, last but not least, a large selection of floor coverings under which this type of heating can be installed. This makes it suitable for floors throughout the entire building, whether it is the living room, bathroom, kitchen or garage.

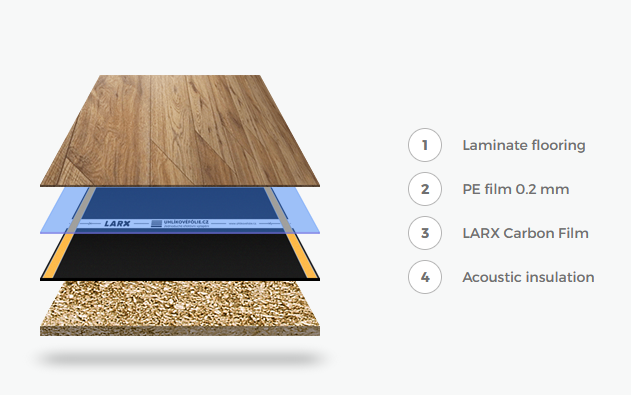

There are two options for where to place the carbon heating film in the floor. Electric heating films are around 0.5mm thick, so they are very thin and negligible in the overall floor composition. If we have a living room with a planned laminate, vinyl, etc. floating floor, the most suitable way is to install the carbon heating film directly under the top floor layer. This way the heating will have a quick response to temperature changes and will have a fast ramp up. If the heating film is placed directly under the stacked floor covering (=dry installation), its called a direct floor heating system.

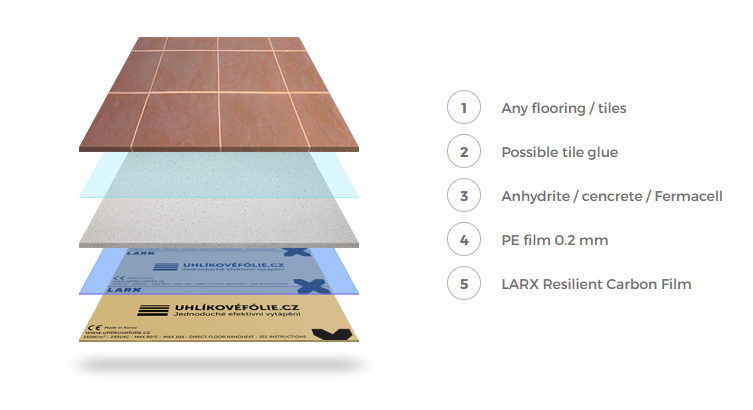

In the case of a non-folded floor covering, e.g. tiles, glued vinyl etc, it is not possible to use the carbon heating film directly under the covering as nothing can be glued directly to the carbon film. The solution is to place the heating film underneath the system floor slab or screed layer – concrete or anhydrite. The heating will then work in a so-called semi-accumulation mode. The heating film will therefore not only heat the room directly through the floor covering, but also through the screed or slab layer. The overall response to changes in the desired temperature and the start-up of the heating system will thus be slightly slower than in direct heating applications, but the heat will remain “accumulated” in the floor even after the heating has been switched off.

There are two variants of installation of the LARX CARBON-FILM.COM heating system – under the screed/floor boards or directly under the floor covering. The heating foil is always anchored to the floor insulation layer (polystyrene or PIR boards if installed under the screed, Hobra/Starlon if installed directly under the floor covering).

Heating film installation under screed or prefabricated floorboards

In the classic installation method under screed or floor boards, the choice of covering is free, it is possible to use a folded floor (click system), glued floor, tiles or trowel. This is the most versatile and widely used solution. The height of the screed/floorboard layer affects the floor’s storage capacity – the thicker the layer, the more heat the floor will store and the slower the space will cool down if the heating is turned off. On the other hand, the more significant the heat accumulation, the slower the response of the underfloor heating as it takes longer for the heat to get through the accumulation layer.

The carbon film is anchored to the floor insulation layer, i.e. polystyrene or PIR boards, when installed under screed or floor boards. This is followed by a 0.2 mm thick layer of PE foil which serves as protection. In the case of poured floors, the heating system is separated from the screed layer by a second layer of covering foil, which acts as a separating layer. The edges are connected to the perimeter expansion joint, with which it forms a so-called “bathtub”. A second foil is not needed when installed under the directly under flooring. When installing undre screed or floor boards, stacked or glued flooring, tiles, trowels, etc. can be used as final floor covering.

The minimum height of the floor composition when installing under screed or floor boards is approx. 5 cm (2 cm PIR board – heating film – 2 cm floor boards – 1 cm any covering). There is no limit to the maximum height of the floor. It all depends on the type of installation, the height of the insulation, the spreading layer in the building where the LARX CARBON-FILM.COM heating system is implemented.

Heating film installation directly under floating floor

In modern, well-insulated houses, the installation of carbon film directly under vinyl or laminate flooring is used. The condition is that it must be folded (click system). This heating system has good dynamics, a fast rise and practically cannot overheat the room. In rooms where a floor other than a stacked floor is planned (bathroom, corridor, etc.), the installation of a carbon film under the screed or floorboard is used. It is not possible to glue any floor covering directly onto the heating film.

When installed directly under a stacked roofing system, the carbon film is anchored into the step insulation layer (Hobra/Starlon). Channels are cut into the insulation boards for cable routing to ensure that the area for laying the prefabricated flooring is level, without any protrusions. The heating film is covered with a 0.2 mm thick layer of PE covering foil. After that, the stacked flooring is assembled without restrictions, so the procedure is the same as if the heating film was not there.

The minimum height of the floor composition when installing directly under the folded covering is approx. 1.5 cm (0.5 cm of the heating foil – 1 cm of the folded covering). The maximum floor height is not limited in any way, usually within 5 cm. It all depends on the height of the insulation, and the height of the installed floor.

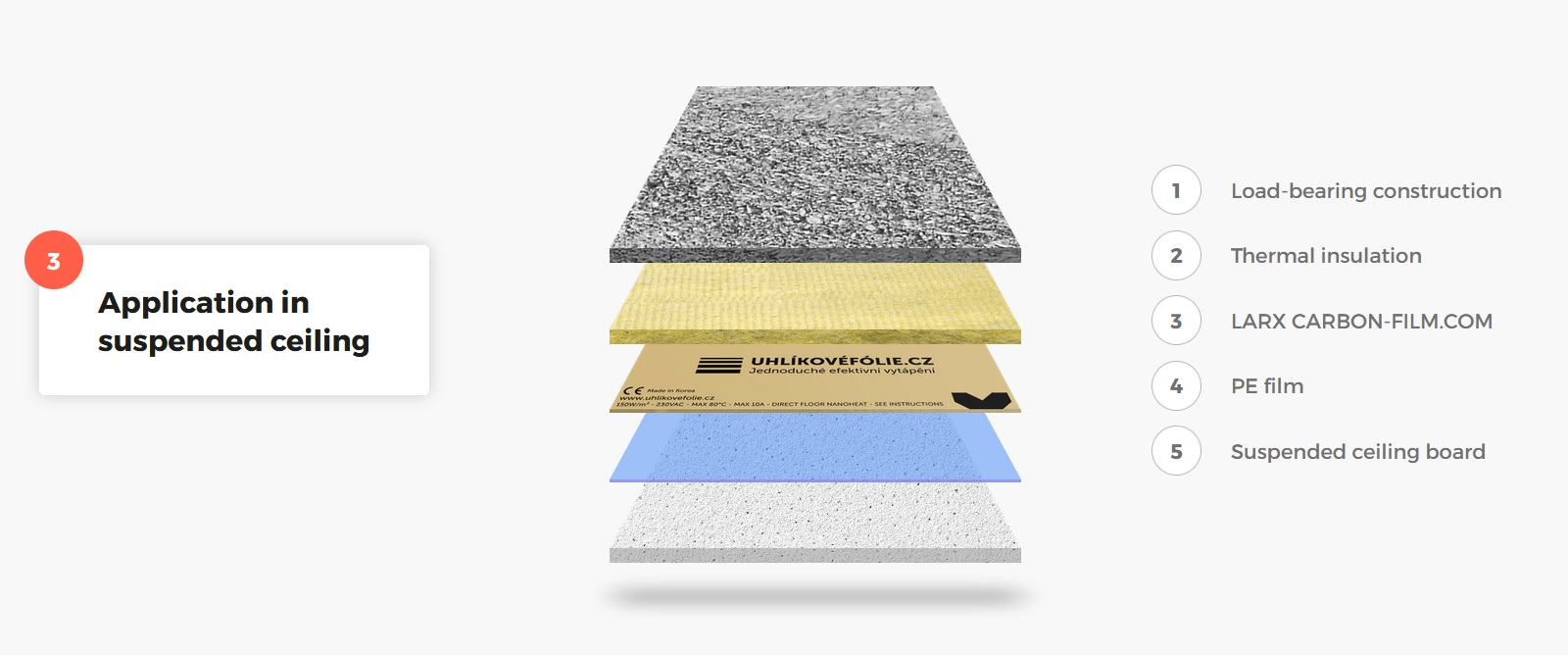

Heating film installation under ceiling

Heating films are not only for underfloor heating systems. They can also be used as ceiling heating. The heating film is placed between the plasterboard ceiling and the thermal insulation of the ceiling. This solution is suitable for renovations where the floor height is not sufficient to use an underfloor heating system. Carbon heating film with higher performance are used for ceiling heating. For underfloor heating there is a standard which states that the temperature of the floor layer should not exceed 29 °C, this limitation does not apply to ceiling heating.

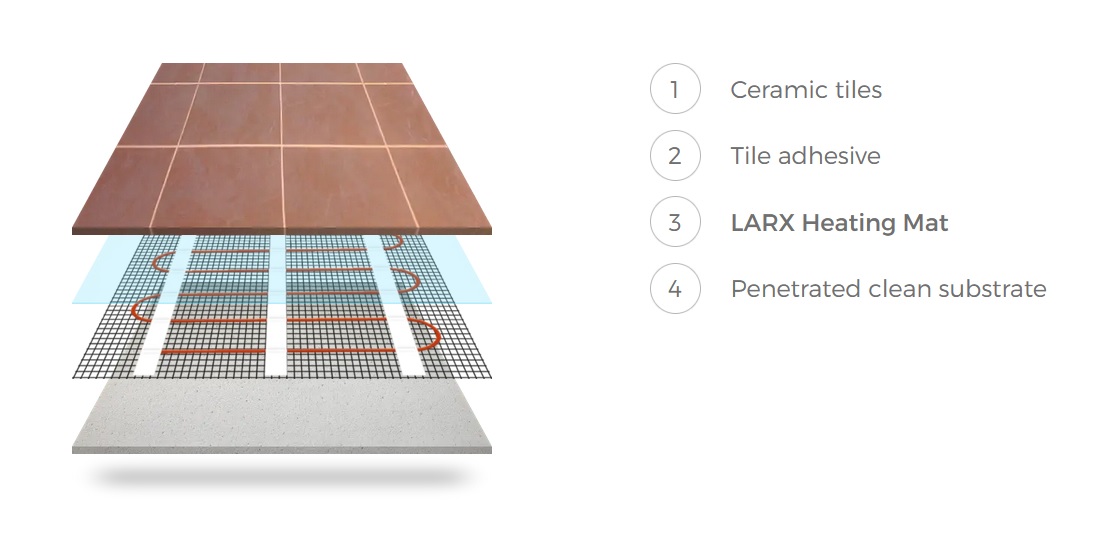

LARX Heating Mats directly under tiles

Heating mats are popular for their quick and easy installation. They can be used both for the main space heating or just for supplementary heating of the floor to a comfortable temperature. Electric heating mats are installed directly under tiles, e.g. in bathrooms and kitchens, or in a low layer trowel, then the floor can also be linen or carpeted. For ease of installation, the heating mat is the most popular heating element.

Heating film regulation

Precise regulation of the underfloor heating is one of the key factors of the entire system. The temperature in the room has a major influence on the feeling of well-being and comfortable living in the home. In addition, correctly selected temperature control means savings on heating costs. Carbon heating films are the ideal heating method in terms of control. In direct heating applications, the heating film start heating the room almost immediately after starting and even in semi-accumulation application, the delay between starting the heating and the temperature rise in the room is minimal, up to half an hour. The heating films are controlled by relays/switches in a 0/1 way, i.e. either heating or not heating. There is no lossy regulation of voltage or current flowing. The thermostat thus completely disconnects the power supply when the desired temperature is reached. The heating films then switch on at intervals of a few minutes a few times an hour, depending on how the room is cooling down.

An important part of any underfloor heating system is a thermostat with a floor temperature sensor. According to the standard, the floor temperature should not exceed 29°C in living rooms (33°C in bathrooms), so it is important to use a thermostat with an internal (which controls the room temperature) and external (which controls the floor temperature) temperature sensor. Our LARX LCD and Wi-Fi thermostats meet all these requirements. In addition, it is possible, for example when using the heating film as a supplementary heat source or in summer when there is no need for heating, to set the control only according to the external sensor and thus use the heating films only to heat the floor to a comfortable temperature.

Are you interested in our implementation of the LARX CARBON-FILM.COM heating system? Do not hesitate and send us your project via the contact form and we will price the heating system for you without obligation.

Česky

Česky