Installation of a heating system using carbon heating films is simple, straightforward and fast. Every more skilled handyman can do it, an electrician should be able to handle the installation without a single problem. In this article, we will share with you our experience in the form of tips and tricks for the installation of heating film, so that your installation is as simple as possible.

The LARX CARBON-FILM.COM heating system has a number of indisputable advantages. Maintenance-free and low-cost operation, low demands on floor space, precise regulation and, last but not least, a large selection of floor coverings under which this method of heating can be installed. It is suitable for floors throughout the whole building, whether it is a living room, bathroom, kitchen or garage.

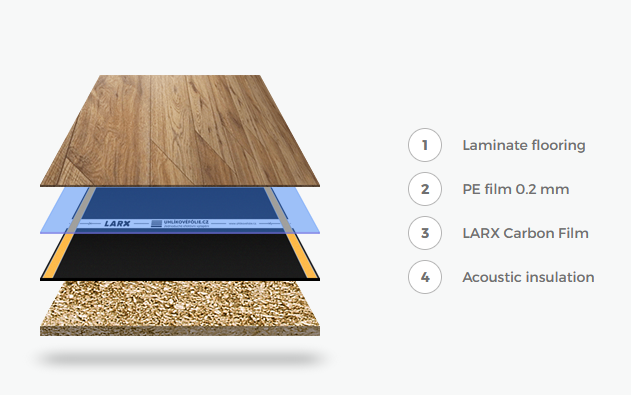

There are two ways to place a carbon heating film in the floor construction. The thickness of the electric heating film is around 0.5 mm, so they are very thin and negligible in the overall height of the floor. If we have a living room with a planned laminate, vinyl, etc. (folded floor) it is possible to install a carbon heating film directly under the upper tread layer of the floor. The heating will thus react quickly to changes in temperature and will have a fast start-up. When placing the heating foil directly under the folded floor covering (= dry type of installation), it is direct underfloor heating.

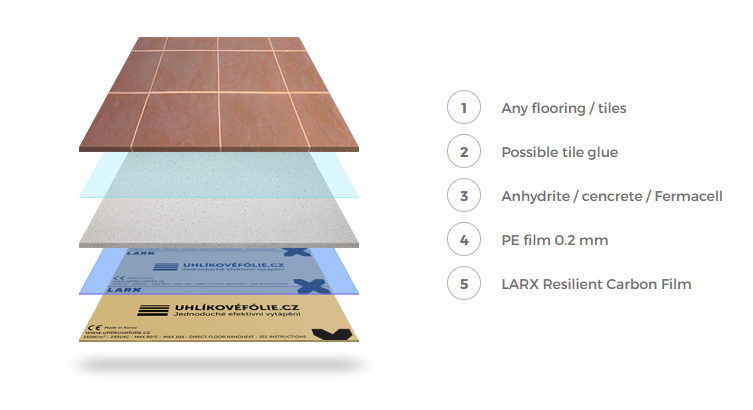

In the case of the implementation of other than folded floor coverings, such as tiles, glued vinyl or trowel, the use of carbon heating film directly under the flooring is not possible, because nothing can be glued directly to the carbon heating film. The solution is to install a heating film under the system floorboards or a layer of screed – concrete or anhydrite. The heating will then work in the so-called semi-accumulative mode. Thus, the heating film will not only heat directly into the room through the floor covering, but also through the screed or board layer. The overall reactions to the change in the required temperature and the start-up of the heating system will thus be slightly slower than in direct heating use, but the heat will remain “accumulated” in the floor even after the heating has been switched off. This variant is the most used, universal, more durable, and therefore suitable for development projects.

Installation tips and tricks video

Before installation

Material shopping

On our website you will find all 3 types of our carbon heating film for purchase, including all necessary installation materials such as wires, connectors, insulating butyl tape or crimping pliers for connectors. Our interactive form will calculate how much other installation material you will need when entering the required amount of carbon heating film. Therefore, during the installation there should not be the slightest problem with the fact that you would miss anything.

Heating film placement

Before the installation itself, it is good to check the dimensions of the room and prepare a laying plan. Basic types and tips for the laying plan of heating films:

- The individual strips of heating foil are distributed with a minimum gap between them.

- We try to design the layout of the strips so that we have the shortest and simplest possible path of the connecting wires and at the same time as few strips / connectors as possible.

- The individual strips of the carbon heating foil must not overlap, the heating foil must not be cut obliquely.

- It is advisable to leave a gap of at least 10 cm around the perimeter around the walls.

- Heating foils are not placed under built-in furniture, kitchen unit and sanitary ware.

- Carbon heating foils cannot be installed directly under the shower enclosure.

- Heating circuits are usually divided according to individual rooms. If the designed output of the heating foils is greater than 16 A, the heating foils in the room must be divided into several circuits using booster circuits and contactor control.

If you are not sure about the ideal placement of heating films in the rooms, division into heating circuits, etc., you can use our services in the form of preparation of complete project documentation, including calculations of heat losses of your building, technical report, construction readiness and laying plan of heating foils. according to which you install the heating system yourself.

During installation

Base layer

Prior to installation, the base layer must be free of all unevenness and dirt. The base layer must be flat. It is always necessary to attach the carbon heating foil to the base layer in a suitable way so that it does not shift / overlap.

Connectors and cables

To install the LARX CARBON-FILM.COM heating system, only our LARX wires have to be used. These are specific cables designed directly for the installation of carbon heating films. They are made of tinned copper, have double electrical insulation and are resistant to high temperatures. Other cables or wires are not suitable for the installation of the LARX CARBON-FILM.COM heating system.

We recommend using our crimping pliers to crimp connectors. Although it is possible to press the connector with, for example, pliers, it can also damage the carbon heating film. Crimping pliers press the connector over the entire surface with exactly the force required for ideal contact, and also facilitate and speed up the entire installation process.

High-quality crimping of connectors, wires and heating film and their insulation is the most important part of the entire carbon heating film installation process.

PE film

Immediately after connecting and insulating the connectors, the carbon heating film must be covered over the entire surface with a protective and insulating polyurethane foil with a minimum thickness of 0.2 mm and a minimum overlap of 10 cm. The individual strips of PE foil need to be precisely glued with tape to create one large area. PE foil on the heating film fulfills the role of both mechanical protection and insulation against moisture. When installing the heating foil under the screed, the PE foil does not play the role of a separating layer. The separating layer for pouring the screed must therefore be formed by laying a second layer of PE foil and taping it to the expansion tape around the walls of the room, thus creating a so-called “bathtub”.

After installation

Immediately after the installation of the heating films and their covering with PE foils, the connection and functionality of the heating system is checked. This check is in two phases – measuring the resistance of the heating circuit and test heating.

Testing the heating system

Test heating immediately after installation can be performed by connecting the heating circuit to the power supply. A contactless thermometer or thermal imager can be used to determine the functionality of the heating, or the heating foils can be heated until the difference is felt. We recommend testing the correct functionality of all stripes of heating film in the room.

Ressistance measurement

Resistance measurement is the simplest and at the same time the fastest way to verify the correct connection and function of carbon heating film. We measure the electrical resistance with a multimeter on the supply wires for the entire heating circuit. The correct value (with a deviation of + -15%) can be calculated according to the formula:

- electrical resistance of the heating circuit = (voltage) ² / (installed heating film surface * heating film power)

Carbon heating film control

The heating films are controlled in a 0/1 manner, ie they either heat or do not heat. They can therefore be controlled by contactors, regulation by voltage change is unnecessarily complicated. An important part of any underfloor heating system is a thermostat with a floor temperature sensor. According to the standard, the temperature of the floor should not exceed 29 ° C in living rooms (33 ° C in bathrooms), so it is important to use a thermostat with an internal (according to which we regulate room temperature) and external (according to which we control the floor temperature) temperature sensor. More information on the regulation of heating foils can be found in this article.

Are you in the process of choosing the heating system for your building? We will be happy to prepare a non-binding price offer for you. Do not hesitate and send us your project via the contact form and together we will find a suitable solution.

Česky

Česky