Underfloor heating has long been a sign of a certain luxury and not everyone could afford it. However, this has changed due to advances in technology, manufacturing and installation processes in recent decades. Nowadays, an underfloor heating system can end up cheaper in the final cost than heating with conventional radiators.

Electric heating is nowadays a common method of heating homes, which is used not only in residential buildings. Electricity is only a carrier of energy and the actual radiation of heat into the room can be done in many ways. The heat source can be, for example, an electric boiler, where water is heated, which is then distributed to heated rooms. This type of heating, which uses water heated in the technical room as a carrier of thermal energy, is called a central heating system. However, carbon heating films are a local system, they work on the basis of direct conversion of electrical energy into heat directly in the heated room.

Carbon heating film and underfloor heating

Electric underfloor heating with the use of heating films offers many advantages. The biggest ones include low acquisition and operation costs, maintenance-free and whole-surface heating. Thanks to its thickness, the LARX CARBON-FILM.COM heating system is suitable for all types of constructions and reconstructions. Heating films are a low-temperature type of heating. That means that they do not cause dust swirling or air drying, so they are an ideal type of underfloor heating for allergy sufferers, asthmatics and other people with respiratory problems.

Carbon heating films are a heat source that converts electricity into heat with an efficiency of 99% (from 100 W of electricity creates 99 W of heat) locally, so the conversion of electricity into heat takes place directly at the place of need (heated rooms). Thus, all energy losses in the transfer of heat from the source to the place of need, which are not negligible in the case of for example hot water heating systems, are eliminated. Carbon heating films can act as a main or additional heat source, ideally in conjunction with photovoltaic panels and home batteries.

Heating films are not only intended for underfloor heating systems. They can also be used as ceiling heating. The heating film is placed between the plasterboard ceiling and the thermal insulation of the ceiling. This solution is suitable for reconstructions where the floor height is not sufficient for the use of a underfloor heating system. Carbon heating foils with higher output are used for ceiling heating. For underfloor heating, there is a standard that states that the temperature of the floor layer should not exceed 29 ° C, this limitation does not apply to ceiling heating.

Construction of carbon heating film

Thickness of the carbon heating film is up to 1 mm, so they are very thin and negligible in the overall height of the floor composition. The supporting part of the heating foil consists of two glued strips, between which a resistance heating element is applied, which is formed by a carbon paste. This paste is made by pressing fine carbon dust, which is used, for example, as a colorant in printer ink. Also, the process of applying carbon paste to the web is similar to printing. The power output of the heating film (or resistance) is affected by the concentration of carbon in the applied paste. At the longitudinal edges of the heating foil there are copper strips which connect the individual strips of carbon paste. Power cables are attached to these copper strips using crimp connectors. The ends of the film and all connections must be carefully insulated, then covered with a polyurethane foil at least 0.2 mm thick.

Direct and accumulative underfloor heating

There are two ways to place a carbon heating foil in the floor composition. If we have a living room with a laminate, vinyl, etc. floating floor, the most suitable is the installation of carbon heating film directly under the upper tread layer of the floor. The heating will thus have fast reactions to temperature changes and will have a fast start-up. When placing the heating foil directly under the folded floor covering (dry type of installation), it is called direct underfloor heating.

In the case of implementation of other than floating floor coverings, such as tiles, glued vinyl or trowel, the use of carbon heating film directly under the floor is not possible, because nothing can be glued directly to the carbon film. The solution is to place the heating foil under the system floorboards or a layer of screed – concrete or anhydrite. The heating will then work in the so-called semi-accumulative mode. Thus, the heating film will not only heat directly into the room through the floor covering, but also through the screed or board layer. The overall reactions to the change in the required temperature and the start-up of the heating system will be a bit slower than in direct underfloor heating, but the heat will remain in the floor “accumulated” even after the heating is switched off.

The amount of energy required (kWh) in direct underfloor heating is only slightly lower than in the semi-accumulative mode, because the electricity consumption does not depend on the type of placement of the foil in the floor, but on the heat loss of the house or room.

Carbon heating film and reflective foil

According to some sellers of heating films, reflective foil can reflect radiant heat towards the room and thus reduce heating costs. But is it really so? No, don’t believe them. The radiant heat is spread between surfaces of different temperatures that do not touch each other and the gap between them is filled with air (not flowing air). Therefore, if we place the heating film directly on the reflective foil, no gap will be created between the heat source and the reflective foil. The heat will continue to radiate down the reflective foil, as if the reflective foil was not there. Reflective foil in combination with carbon heating film is therefore only a marketing ploy of insincere sales representatives of some sellers of heating films.

Carbon heating film and electromagnetic smog

Electromagnetic smog, ie radiation that is created by the passage of an electric current through metal conductors. But carbon is not a metal. Heating films have negligible metal components and therefore the production of electromagnetic smog is minimal, especially in comparison with heating cables or mats, which are made of metal, and therefore the production of smog in the room is much higher. The LARX CARBON-FILM.COM heating system meets all European and Czech standards and the has strictest European certificates for operation in living rooms.

Carbon heating film regulation

Precise regulation of underfloor heating is one of the key factors of the whole system. The temperature in the room has a major impact on the feeling of well-being and comfort in the home. In addition, the right temperature control means savings on heating costs. From the point of view of regulation, carbon heating foils are an ideal way of heating. In the case of direct underfloor heating, the film starts to heat the room almost immediately after start-up, and even in the case of semi-accumulative use of heating film, the delay between starting the heating and the temperature rise in the room is minimal, up to half an hour. The heating foils are controlled by means of contactors in a 0/1 manner, ie they either heat or do not heat. there is no lossy regulation of voltage or flowing current. The thermostat thus completely disconnects the power supply when the required temperature is reached. The heating foils then switch at several-minute intervals a few times an hour, just as the room cools down.

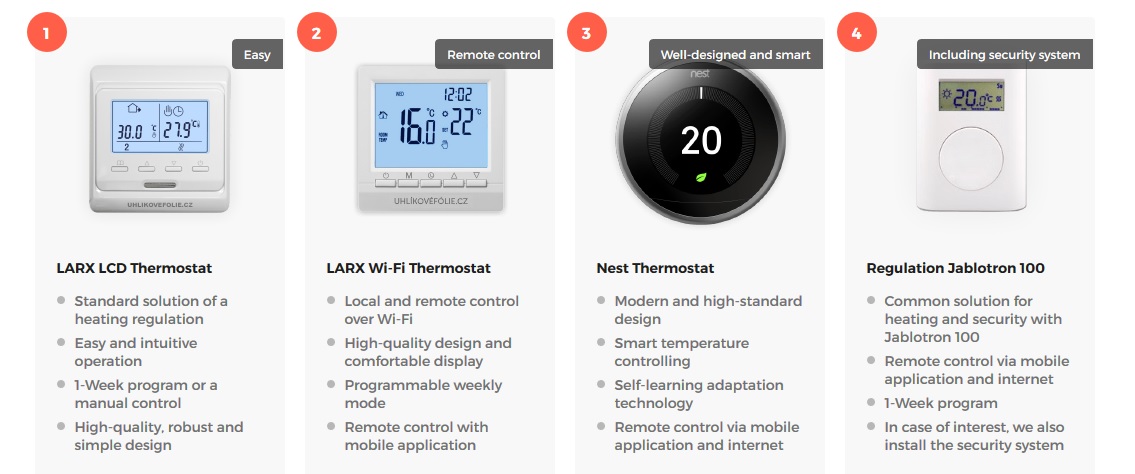

An important part of any underfloor heating system is a thermostat with a floor temperature sensor. According to the standard, the temperature of the floor should not exceed 29 °C in living rooms (33 °C in bathrooms), so it is important to use a thermostat with an internal (according to which we regulate the room temperature) and external (according to which we control the floor temperature) temperature sensor. Our LARX LCD and Wi-Fi thermostats meet all these requirements. In addition, it is possible, for example in summer when there is no need to heat, to set the control to only follow the external sensor and thus use the heating film only to heat the floor to a comfortable temperature.

“Turnkey” heating system installation

The simplest and at the same time laborless way of purchasing the LARX CARBON-FILM.COM heating system is a “turnkey” installation. In the case of a “turnkey” implementation, all responsibility for the installation and proper functioning of the heating system passes to us as the installation company, and we are thus able to guarantee the operability of the heating system for 15 years. The service life of carbon heating film exceeds 30 years and is thus higher than the expected service life of the floor itself.

“Turnkey” installation process

- The initial contact usually takes place via a form on the website, the more documents we have for creating a price offer (floor plan, floor compositions and other details of the building), the better.

- We will prepare and send an individual price offer.

- If you are interested in the LARX CARBON-FILM.COM heating system, we will prepare a heating project.

- As part of the project preparation, we will visit the building, which we will go through together with the owner and discuss all the details of the implementation. We will provide the owner with a description of the construction readiness together with the specific electrical installation material for the selected regulation.

- The output is a complete heating project with the LARX CARBON-FILM.COM system

- We continuously consult with the investor on the course of preparations.

- We will install the LARX CARBON-FILM.COM heating system on the agreed date

- Finally, we hand over the heating system and train the residents.

DIY installation of carbon heating film

Another way to purchase an underfloor heating system using carbon heating films is to install them yourself.

The implementation of a heating system using carbon heating films is simple, straightforward and fast. Every more skilled handyman can do it, electrician should be able to handle the installation without a single snag and no problem. In addition, you can use our services in the form of preparation of complete project documentation, including calculations of heat losses of your building, technical report, construction readiness and installation plan of heating films, according to which you will then install the films yourself and get a feeling of well done job.

Carbon heating film and necessary installation materials

On our website you will find all 3 types of our carbon heating film for purchase, including all necessary installation materials such as wires, connectors, insulating butyl tape or crimping pliers for connectors. Our interactive form will calculate how much other installation material you will need when entering the required amount of carbon heating film. Therefore, during the installation there should not be the slightest problem with the fact that you would be missing something crucial. We will be happy to advise and help you with the right choice of our carbon heating film and the purchase of installation material for your underfloor heating system.

LARX Carbon Kit

LARX Carbon Kit is a professionally prepared, connected and insulated strip of carbon heating foil with 3 meters long supply cables intended for self-installation. All you have to do is unpack the heating film strip, place it, fasten it in the designated place and cover it with a cover foil. This is followed by the installation of a folded floating floor in the case of a dry installation, or the pouring of a concrete screed in the case of a wet installation.

On our website you will find all important information (manuals, videos, etc.) needed for trouble-free installation and connection of the LARX Carbon Kit by yourself.

The LARX Carbon Kit can be purchased in all Hornbach hobby market stores in the Czech Republic and Slovakia, online here, or in one of the largest e-shops in the Czech Republic – MALL.CZ.

Demo kit of LARX CARBON-FILM.COM heating system

You can also try the LARX CARBON-FILM.COM heating system without obligation thanks to our LARX demo kit. It contains LARX durable carbon film with an output of 150W / m² and LARX carbon film with an output of 180W / m². In addition, a set of 4 connectors, double-insulated supply cables, butyl tapes and installation instructions. The set also contains information leaflets of the LARX CARBON-FILM.COM heating system. It is therefore possible to test the functionality of heating foils on your own.

You can find more about underfloor heating with carbon heating films, our installations and references, and other important information on our blog, Facebook or instagram. You can also watch a time-lapse video of the installation of LARX CARBON-FILM.COM heating system in a multifunctional space in Prague, or a time-lapse video of the installation of LARX UHLÍKOVÉFÓLIE.CZ heating system in a family house near Cesky Krumlov, South Bohemia.

Are you interested in LARX CARBON-FILM.COM heating system? We will be happy to prepare a non-binding price offer for you. Do not hesitate and send us your project via the contact form and together we will find a suitable solution for you.

Česky

Česky